Certified quality

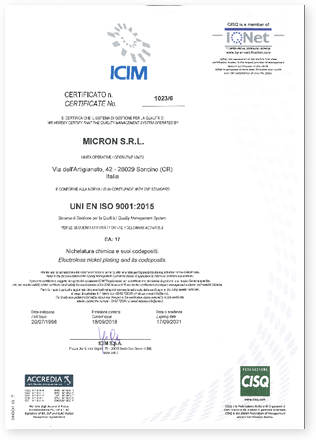

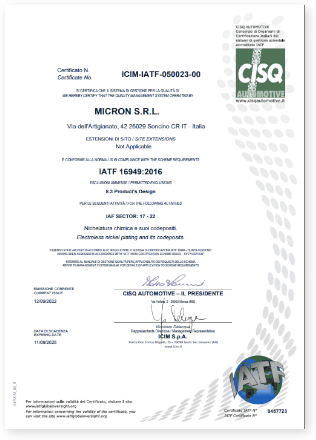

The certification of Micron and Durox's quality management systems is only the starting point for us to offer a service of excellence. Micron and Durox's quality management systems are ISO 9001 certified. Micron has also achieved IATF 16949 certification to serve the automotive sector.Highly advanced plant

Every year we allocate substantial investments to updating of our production plant and machinery and our internal company systems. This makes it possible to guarantee high quality standards, fast treatment turnaround, even for high volumes, safe workplaces for people and respect for the environment.Customer service

We understand that the service we supply extends far beyond the treatment process. We therefore seek to develop a relationship as both a supplier and partner. Thanks to our experience and a state-of-the-art R&D laboratory, we support the customer throughout the design process, from the base material to the choice of the most suitable surface treatment.Specialization and know-how

Our choice has always been to specialize in technical surface treatments applied to precision mechanics, particularly in electroless nickel plating and anodizing. Our legacy knowledge base is composed of our treatment processes, all of which designed, developed, and constantly refined in-house. This focus has allowed us to supply state-of-the-art surface treatments that meet and exceed customer requirements.