NIPLATE® LINK

Electroless Nickel for Busbars and Solderable Components

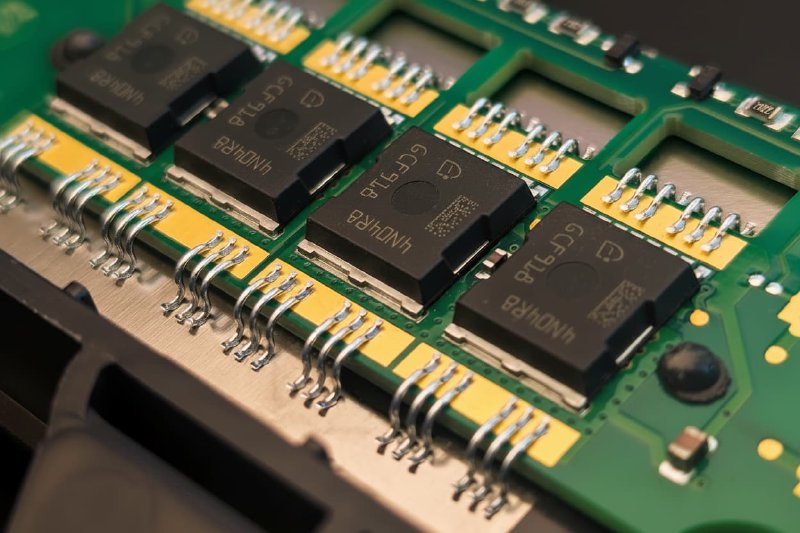

Niplate Link is an electroless nickel plating treatment, covered by a patent application, specifically designed for electrical and interconnection components such as copper busbars, connectors and parts intended for soldering and brazing.

The coating provides a solderable, corrosion-resistant and long-term stable surface, significantly reducing the risk of surface oxidation that could compromise joint quality.

Thanks to the high uniformity and strong adhesion of the deposited layer, Niplate Link improves the reliability of electrical connections in power distribution systems and reduces failures caused by joint defects.

It is ideal for busbars and electrical components used in electric vehicles, inverters, battery packs and power converters, where connection reliability and long-term durability are critical requirements.

In addition, due to its excellent corrosion resistance, it can also be used in water-cooled circuits, preserving surface passivation and protecting the base material.

Compared to traditional electroplated solutions, Niplate Link offers a repeatable, cost-effective process free of precious metals, optimized for high-productivity industrial manufacturing, particularly for components with complex geometries.

Declaration of Conformity

Declaration of Conformity