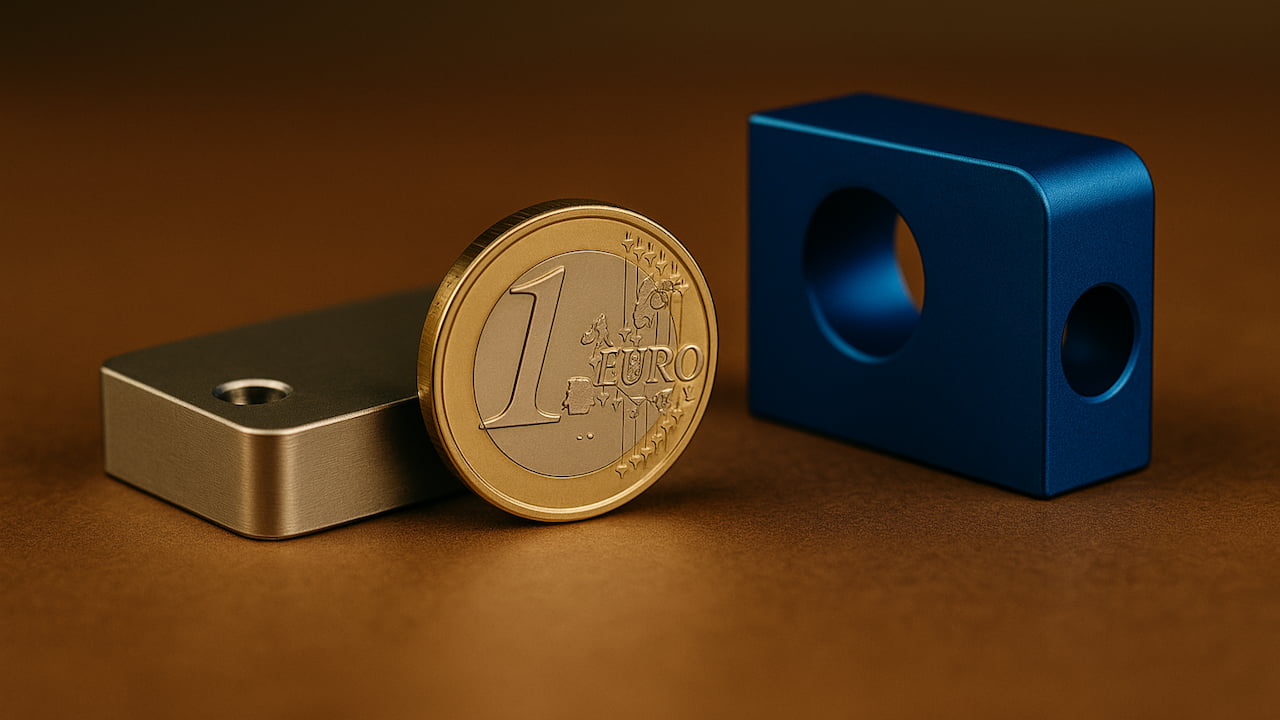

Electroless Nickel and Anodizing: What Affects the Price?

One of the most common questions we receive from those approaching a technical surface treatment for the first time is:

“How much does it cost per kilo?”

Whether we’re talking about electroless nickel plating or anodizing, the correct answer is: it depends.