One of the most common questions we receive from those approaching a technical surface treatment for the first time is:

“How much does it cost per kilo?”

Whether we’re talking about electroless nickel plating or anodizing, the correct answer is: it depends.

It may sound like a vague answer—especially for those who need to quickly calculate a total part cost—but it’s an honest one: there is no universal or standard price list, because the final cost depends on many variables.

There’s no standard price: here’s why

Unlike simpler or more widespread processes like zinc plating or painting, electroless nickel plating and anodizing are technical treatments that depend on many factors: the type of metal alloy, the geometry of the part, the required surface specifications, and the intended end use.

For this reason, you cannot define a fixed €/kg or €/dm² price: each job must be evaluated individually, and every quote is custom-built.

What affects the cost of a surface treatment?

The main cost factors are similar for both nickel plating and anodizing:

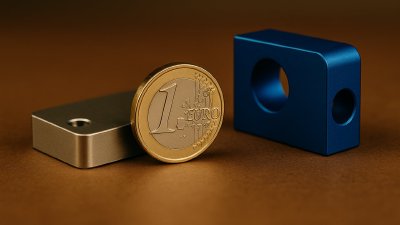

- Part size and geometry: surface area, weight, and complexity directly affect process time and material consumption.

- Base material: steel, aluminum, copper, and other alloys require different pretreatments. In anodizing, the aluminum alloy type also influences the final appearance and performance.

- Treatment type: there are standard, more economical treatments, and advanced versions (composite, high thickness, or colored) with higher costs.

- Coating thickness: the thicker the coating, the more time, material, and energy required.

- Production method: mass processing (barrel plating, not applicable to anodizing) is cheaper than rack plating, where parts are handled individually.

- Quality checks, certifications, packaging: additional requirements affect total cost.

- Batch volume: larger batches benefit from economies of scale and lower unit costs.

How Much Does It Cost?

In precision engineering, electroless nickel plating and anodizing are high-value treatments that add relatively limited cost to the finished component. On average, they account for about 5 % to 20 % of the part’s value, depending on geometry, base material, technical specifications, and production volumes.

For a rough initial estimate, treatment costs typically range from € 0.50 to € 5.00 per dm²:

- Lower range → standard treatments on simple geometries and medium-to-large batches

- Upper range → high-performance treatments or parts with special requirements (greater thickness, Ni-P composites, special colors)

Every project deserves a tailored assessment. Our technical team is available to prepare clear, customized technical-economic proposals.

Which treatment should you choose?

The choice of treatment shouldn’t be based on price alone, but rather on the base material, end use, and the required performance.

A brief comparison between the two

Electroless nickel plating (for steel, copper alloys, aluminum):

- Excellent thickness uniformity, even on complex geometries

- Superior corrosion resistance compared to traditional galvanic coatings

- High surface hardness, up to 1000 HV with heat treatment

Anodizing (only for aluminum alloys):

- Lightweight and ideal for parts where weight-to-performance ratio is critical

- Wide range of aesthetic finishes, including color options

- Good abrasion and wear resistance, especially with hard anodizing

- Excellent corrosion resistance in neutral environments

Practical examples

- A mechanical part in steel for a corrosive environment? → High-phosphorus electroless nickel plating

- An aluminum bracket requiring a colored finish? → Anodizing, standard or decorative

- A steel shaft subject to wear and friction? → Nickel plating with wear-resistant particles or post-hardening

- An aluminum component requiring surface hardness and wear resistance? → Hard anodizing

Request a quote

To get an accurate and detailed quotation, you can send us a request including:

- A technical drawing of the part

- Desired surface treatment specifications

- Estimated production volume

- Any special requirements (e.g. certifications, testing, packaging)

📩 Email us at segreteria@microncoatings.it - Our technical team will respond with a clear, customized commercial proposal.