NIPLATE® 600 SiC

Electroless Nickel with SiC

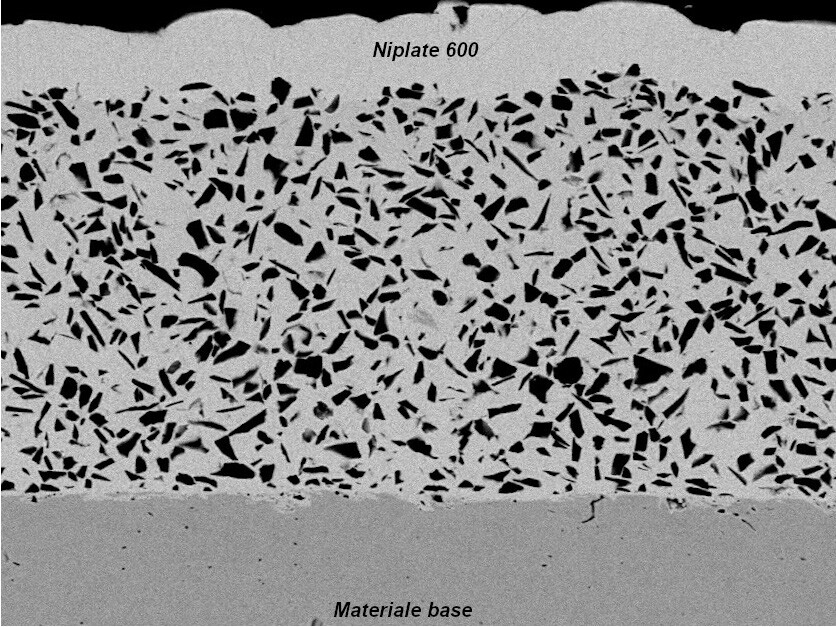

Niplate 600 SiC is a composite coating of medium phosphorus (5-9%) electroless nickel and silicon carbide crystals (SiC) in a concentration of 20-30%.

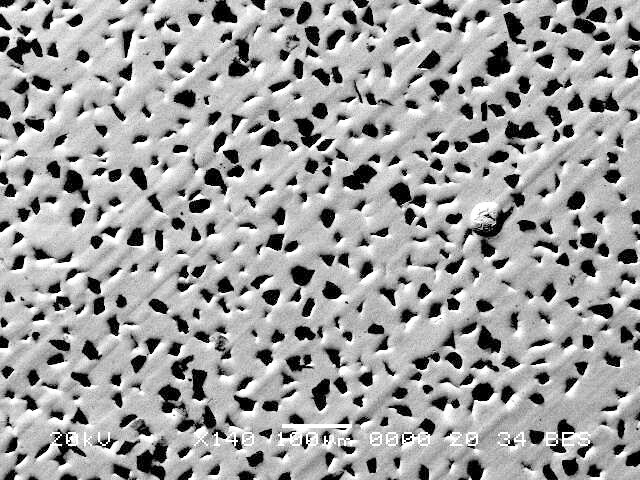

During the nickel plating process microscopic particles of silicon carbide are co-deposited in the film. The layer is thus composed of a nickel-phosphorus alloy matrix with uniformly distributed superhard silicon carbide granules.

Silicon carbide is classified among superhard materials because its hardness value is above 2000 HV, only slightly lower than that of diamonds. Due to this property, silicon carbide is widely employed as an anti-wear material.

Thanks to the presence of silicon carbide granules, the Niplate 600 SiC coating offers very high wear resistance, superior also to hard chrome. This is why the material is employed for critical applications, in the presence of sliding movements and high levels of wear. It is widely used to protect engine components, in the textiles sector, and in motor sports.

Technical datasheet

Technical datasheet