NIPLATE® 500 PTFE

Electroless Nickel Plating with PTFE

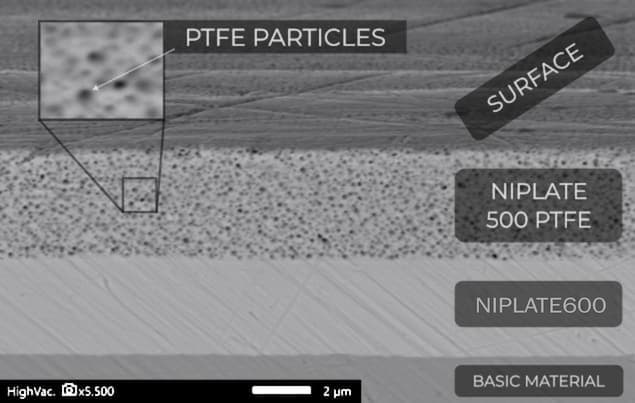

Niplate 500 PTFE is a composite coating of high phosphorus (10-13%) electroless nickel containing 25-35% of PTFE particles.

PTFE nanoparticles are co-deposited in the matrix during deposition of the nickel film. The film is thus composed of a nickel-phosphorus alloy matrix in which the PTFE particles are uniformly dispersed.

PTFE is a polymer with certain specific properties. It is completely chemically inert and immune from attack by almost all chemical compounds. It offers excellent surface smoothness, a low friction coefficient, and non-stick properties.

The Niplate 500 PTFE coating thus combines the intrinsic properties of electroless nickel and PTFE. It offers hardness values on a par with steel, together with low friction coefficient and releasability characteristics.

The low friction coefficient recommends the material for applications with sliding parts, such as solenoid valve tube assemblies and moving cores, and technical gas pressure reducer components. The non-stick property makes the coating suitable for use in the plastic moulding and forming sector, and in metering and control devices for viscous liquids, adhesives, and hot water.

Technical datasheet

Technical datasheet