SURFACE TREATMENTS

WE PROTECT YOUR SURFACES

A reliable partner of the Italian and European mechanical engineering industry since 1973

MICRON COATINGS GROUP was born from the experience started in 1973 with the establishment of Durox srl, one of the first Italian companies to provide hard anodizing treatment of Aluminium. Subsequently Micron srl was founded in 1985, specializing in electroless nickel plating treatments.

Operating in the metals treatment and coating sector, the group stands today as a consolidated supplier recognized throughout Europe. Steady growth over the years has allowed Micron Coatings Group to become a point of reference among the main companies in the precision mechanical engineering sector.

Our treatments are used primarily in the automotive, pneumatics, medical, packaging, textiles, motor sports, cycles and motorcycles, maritime, and aerospace sectors.

For more than 40 years our goal has been total customer satisfaction, achieved thanks to our technical know-how and constantly updated skills, plant, and production processes.

More information

THE CHARACTERISTICS THAT MAKE US UNIQUE

CUSTOMER SERVICE

IMMEDIATE QUOTATIONS

CERTIFICATIONS OF CONFORMITY

STATE-OF-THE-ART LABORATORY

IMMEDIATE TECHNICAL SUPPORT

PROFESSIONALISM

NO QUALITY SHORT CUTS

AUTOMATIC 4.0 PLANTS

RELIABLE TREATMENT TIMES

PRESTIGIOUS COMPANIES THAT USE OUR COATINGS

Thanks to a fully equipped surface characterization laboratory, we assist customers in choosing the correct treatment for their application. We support customers with laboratory tests and analysis to define the required surface characteristics.

Many high profile Italian and European companies use our services and treatments.

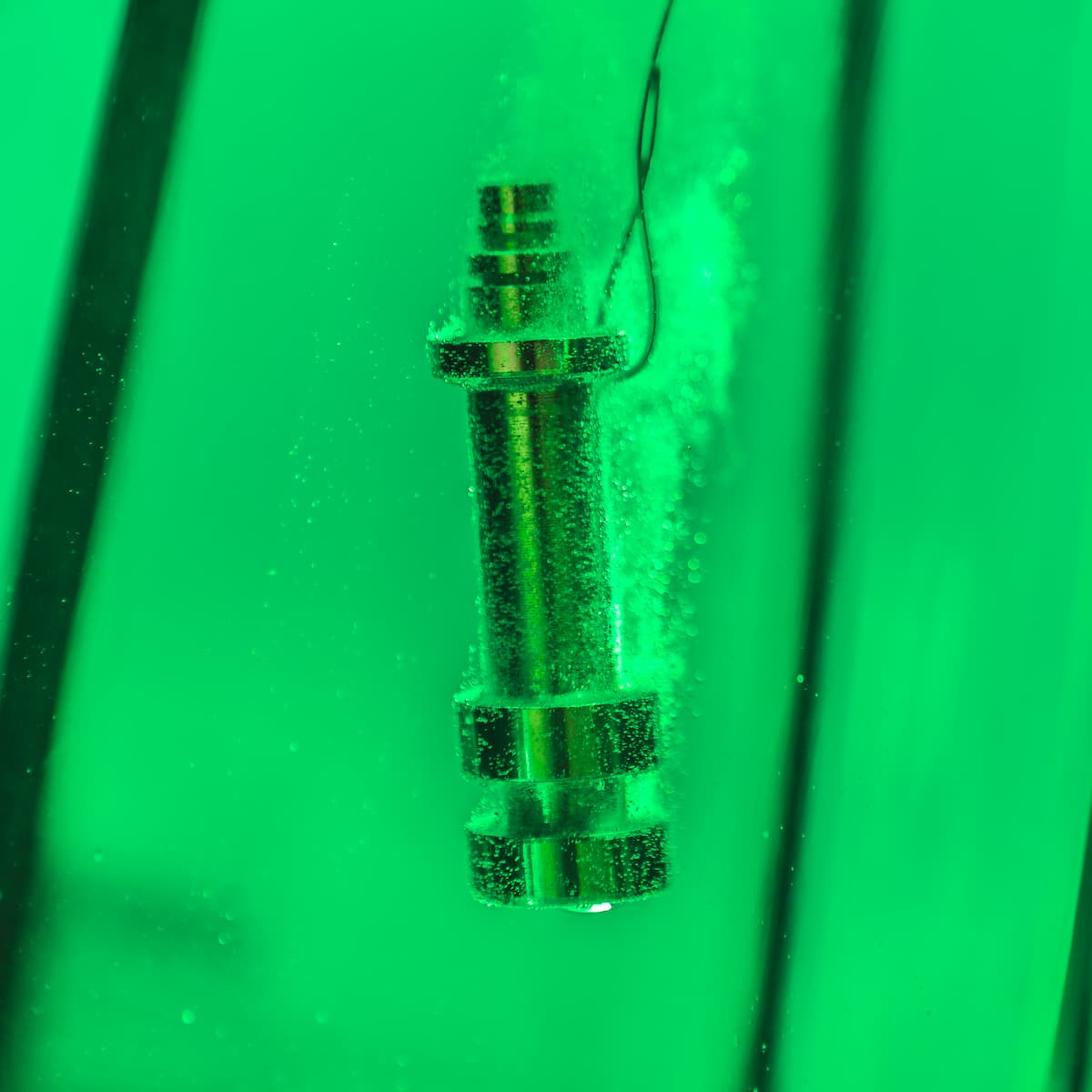

ELECTROLESS NICKEL PLATING

Electroless nickel plating is a chemical process of nickel-phosphorus alloy deposition performed by immersion in a nickel salt aqueous solution. It allows machined components having complex geometries to be coated with a metallic film, with uniform thickness over the entire surface.

This process differs from nickel electroplating due to the deposition method and surface characteristics. Electroless nickel plating is a functional treatment that imparts enhanced characteristics in terms of uniform coating thickness, hardness, wear, and corrosion resistance.

Thanks to its characteristics and the possibility of plating all metals, it is the most widely used coating in the mechanical engineering sector.

More informationALUMINIUM ANODIZING

Anodizing is an electrolytic process that allows the formation of a oxide film on the surface of Aluminium alloy parts. This is the most widely used treatment on Aluminium because it imparts excellent surface properties at limited cost.

The anodizing types most widely used in industry are clear anodizing and hard anodizing, and they differ in terms of both surface characteristics and treatment processes.

Hard anodizing is preferable when the surface characteristics of hardness, wear and corrosion resistance are to be maximized. Clear anodizing is used as a light surface protection against corrosion, wear, and scratches.

More information